Industrial hydrogen production from coal is good for large-scale hydrogen production or when no other suitable feedstock is available.

This process uses methanol and demineralised water from convenient sources as raw materials, which are catalytically converted over a specialised catalyst at 220-280°C into a reformed gas containing mainly hydrogen and carbon dioxide.

Variable Pressure Adsorption (VPA) CO₂ removal process is widely used in ammonia, methanol, butanol decarbonisation units and urea, soda ash, industrial CO₂ purification CO₂ units as well as chi gas and CO₂-containing tail gas recovery units due to its high degree of automation, convenient adjustment of removal accuracy, wide range of application, low energy consumption, and other features.

PSA method of biogas concentration is to use adsorbent to separate methane, carbon dioxide and nitrogen in biogas, so as to achieve the purpose of methane concentration.

Hydrogen from light hydrocarbon water vapour reforming is also a relatively traditional technology, and was previously commonly used for large-scale hydrogen supply, e.g. above 5000 m3/h.

In industrial hydrogen purification by pressure swing adsorption (PSA), the adsorbents generally adsorb the easily adsorbed components out of the gas mixture at ambient temperature and high pressure, while the not easily adsorbed components (such as hydrogen) flow out from one end of the bed as the product

The company's proprietary technology developed for low concentration gas, after fully analysing the nature of the raw gas, adopts variable pressure adsorption under micro-pressure conditions to separate CH4 and N2/O2.

Raw gas whose main component is CO can be converted to CO2 and H2 mainly through the conversion reactor, which can be used as one of the main raw gases for hydrogen production.

Barren coal gas is characterised by large gas volume, low pressure, complex impurity content and low hydrogen content. In addition to being utilised as power generation, hydrogen can be extracted and used as feedstock gas for chemical products such as coal tar hydrogenation, ethylene glycol and synthetic ammonia.

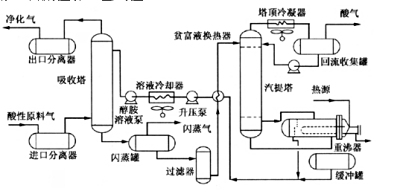

A typical process for amine desulphurisation and decarburisation consists of four parts: absorption, flash evaporation, heat exchange and regeneration (stripping).

Because blast furnace gas contains organic sulphur, H2S and other impurities, using blast furnace gas etc. as fuel, SO2 in the flue gas cannot reach the emission standard. There are two main measures for emission reduction: desulphurisation of blast furnace gas or flue gas desulphurisation at the end.

Coke oven gas enters into the lower part of the naphthalene scrubbing tower, firstly, with the naphthalene-rich scrubbing oil containing 4-8% of naphthalene entering the middle of the tower in countercurrent contact, naphthalene is washed by coarse, and then by the top of the tower containing naphthalene less than 3% of the low naphthalene scrubbing oil refined naphthalene, and then through the top of the tower after the defoamer to remove the oil, liquid separation is sent out of the naphthalene removal tower.

FAX:028-86198015

ADD:13/F, Building 1, Caiji International, No. 595 Jinzhou Road, Jinniu District, Chengdu, China