West China Chemical: Zhejiang Petrochemical Refining and Chemical Integration Project Phase II 1#32000 standard cubic metre/hour hydrogen gasification and concentration plant project progressing well

Huaxi Chemical Technology July 11 news, by Chengdu Huaxi Chemical Technology Co., Ltd. construction of Zhejiang Petrochemical 40 million tons / year refining and chemical integration project phase II project 1 #32000 standard cubic meters / hour gasification hydrogen thickening device design phase progress smoothly.

Huaxi Chemical Technology July 11 news, by Chengdu Huaxi Chemical Technology Co., Ltd. construction of Zhejiang Petrochemical 40 million tons / year refining and chemical integration project Phase II Project 1 # 320,000 standard cubic meters / hour coal gasification hydrogen enrichment plant design phase is progressing smoothly.

Chengdu Huaxi Chemical Technology Co., Ltd. won the bid for the hydrogen concentration plant of Zhejiang Petrochemical 40 million tonnes/year refining and chemical integration project phase II project by virtue of its strong comprehensive strength, perfect technical solutions and advanced management concepts. The unit has a nominal feedstock handling capacity of ~380,000 standard cubic metres/hour, designed operating flexibility of 50~110%, product hydrogen purity ≥99.9%, hydrogen pressure ≥4.9MPa.G, continuous operation cycle of more than 4 years, and device life of ≥20 years, which is a large-scale, high-pressure hydrogen PSA plant in China for hydrogen production from coal.

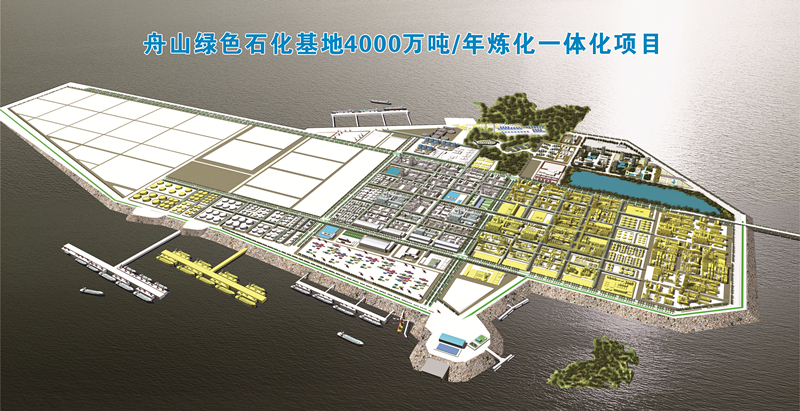

Zhejiang Petrochemical 40 million tonnes/year refining and chemical integration project, is a key project in Zhejiang Province. Ltd. by Zhejiang Rongsheng Holding Group Co., Ltd. investment, a total investment of up to 173 billion yuan of Zhejiang Petrochemical Company Limited large-scale refining and chemical integration project, Zhoushan green petrochemical industry base is the core project.

Zhejiang Petrochemical 40 million tonnes of refining and chemical integration project, is the domestic mixed ownership under the larger refining and chemical projects, has been attracting attention, and Zhejiang Petrochemical has become a larger domestic, the world's fifth largest refinery, the third phase of the project was completed and put into operation, refining scale of Hongda! The project has been highly valued by the State Council, the National Development and Reform Commission, the State Oceanic Administration and other central ministries and commissions, as well as the Zhejiang Provincial Party Committee and Provincial Government.

Zhejiang Province, Zhejiang Petrochemical put forward 10 words of construction standards, namely "private, green, international, trillion, flagship". With reference to the requirements of international first-class petrochemical bases, the Zhejiang Petrochemical project is carried out with reference to international advanced standards from design to construction, and from process technology to the selection of production equipment.

Firstly, the plant is large-scale. Its main installations have reached large/extra-large economic scale, ranking among the world's leading levels. 62% of the project's refinery products are used as feedstock for ethylene and aromatics.

Secondly, the application of large hydrogenation, catalytic and reforming technologies makes the total process of the project more optimised; with a refining capacity of 40 million tonnes/year, the coking unit only has a capacity of 3.2 million tonnes/year, while the hydrogenation capacity exceeds 36 million tonnes/year; and the application of high-efficiency refining and chemical hydrogen-rich recycling technology makes 83% of the hydrogen come from the by-production of the reforming unit.

Thirdly, the products are high-end. Gasoline and diesel fuel have reached the National VI standard. Downstream products include PX and glycol, high-end polyolefin materials and high-end polycarbonate.

Based on the high standard of the project, top global petrochemical and energy companies such as Shell, BP, Total, Honeywell, PetroChina, Sinopec, Sinochem Group, Chengdu Huaxi Technology and others are involved in the cooperation of the project's construction to varying degrees.

Scan the QR code to follow Yizhi Technology