New Ionic Liquid Desulphurisation (ILDS) Technology for Treatment of Krause Tail Gas

The absorption capacity of ionic liquid for sulfur dioxide is very strong, the amount of solvent recycling is only 1/15~1/5 of MDEA solvent, and the consumption of public works is much lower than that of MDEA solvent absorption and regeneration.

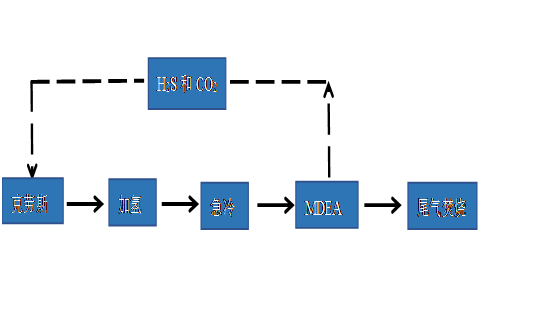

1.1 Conventional process

"Klaus sulfur + hydrogenation reduction absorption tail gas treatment" process as attached Figure 1

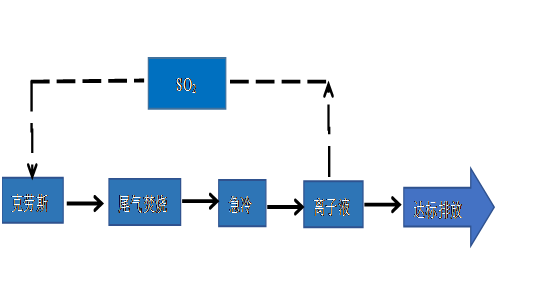

1.2 Ionic liquid desulphurisation technology to treat Krause tail gas new process

The process of "Krause sulphur production + ionic liquid absorption tail gas treatment" is shown in Figure 2.

1.3 Comparison of process description

1) The regenerated acid gas returned to Klaus Sulphur by solvent regeneration in the process of "Klaus Sulphur + Hydrogen Reduction Absorption Tail Gas Treatment" is H2S; the regenerated acid gas returned to Klaus Sulphur by ionic liquid regeneration in the process of "Klaus Sulphur + Ionic Liquid Absorption Tail Gas Treatment" is SO2. The regenerated acid gas in the process of "Klaus Sulphur + Ion Liquid Absorption Tail Gas Treatment" is SO2.

2) There is no tail gas hydrogenation and reduction process in the process of "Klaus Sulphur + Ion Liquid Absorption Tail Gas Treatment".

1.4 Technical advantages of the new process

1) There is no need for Klaus tail gas hydrogenation and reduction process, and no consumption of hydrogen source; construction investment and operation costs are lower.

(2) The absorption capacity of ionic liquid on sulfur dioxide is very strong, the solvent cycle volume is only 1/15~1/5 of MDEA solvent, the consumption of public works is much lower than MDEA solvent absorption and regeneration, the energy consumption is lower, and there is an advantage in the production cost.

(3) The concentration of sulfur dioxide in the purified gas after ionic liquid absorption can be guaranteed to be no more than 50mg/Nm3, and the sulfur dioxide yield in the tail gas can reach more than 99.5%. If you want to further reduce the concentration of sulphur dioxide in the exhaust gas, as long as the operating parameters are moderately adjusted, no need to modify the device, and the production cost will not increase.

(4) The ionic liquid only absorbs sulphur dioxide, there is no problem of co-absorption of CO2 by MDEA solvent, and it has the incomparable advantage of MDEA solvent absorption for the treatment of acid gas of coal chemical industry which contains very high CO2. It eliminates the side effects brought by a large amount of CO2 circulation, and the equipment size can be reduced with lower construction investment.