环保节能技术

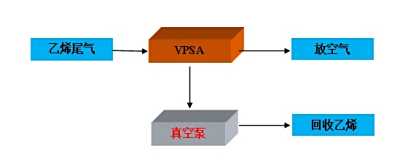

In recent years, with the enhancement of people's awareness of environmental protection, the international and domestic environmental protection requirements for petrochemical plants, as well as from the waste recycling and reuse, reduce production costs, and create higher economic benefits for the enterprise on the consideration of the process of ethylene, propylene plant tail gas recovery have greater social and economic benefits.

Oil tanks, loading emission gas, petrochemical and chemical production of VOC-containing tailpipe gas, the first variable pressure adsorption concentration, and then condensation recovery process, so as to meet the requirements of environmental protection emissions, but also to recover part of the organic matter.

After the vinyl chloride tail gas is divided into liquids by the liquid separation tank, there are still a large amount of vinyl chloride and acetylene, and the vinyl chloride and acetylene are concentrated and recovered by the adsorption method, which is of high economic value.

There are two mainstream denitrification technologies (1) selective catalytic reduction (SCR), (2) selective non-catalytic reduction (SNCR).

The by-product of ammonia desulphurisation is the fertiliser ammonium sulphate, with approximately 4 tonnes of ammonium sulphate being by-produced for every 1 tonne of ammonia, the economics of which depend on the prices of ammonium sulphate and ammonia.

HDS desulphurisation and de-cyanidation technology belongs to wet redox method, which is a desulphurisation method with distinctive features developed by Chengdu Huaxi together with scientific and technological personnel of ammonia and coking industries, and it can make the removal rate of H2S in the gas reach at least 99.9%, and the removal rate of HCN reach more than 97%.

Our company provides waste acid regeneration technology and complete set of plant turnkey business, also provides technical services, technical transformation, spare parts sales of waste acid regeneration plant business.

The regeneration of waste hydrochloric acid in iron and steel mills mainly solves the recycling of hydrochloric acid, reduces the discharge of sewage, and recycles iron powder, and its main role is to solve the problem of environmental protection.

Specialised equipment for acid regeneration: especially exhaust fans for acid regeneration, acid regeneration lances, rotary valves, graphite heat exchangers with cooling method (all of the above are patented by our company).

Adopting the internationally recognised new catalytic oxidation purification technology, the catalytic purification tower adopts a new type of internal cooling unit, so that the temperature distribution of the bed is in the appropriate reaction area, the normal production of heat balance, reducing the use of electric furnaces, and prolonging the life of the catalyst.

The desulphurisation and decarbonisation gas purification technology using polyethylene glycol dimethyl ether as the absorbing liquid is known as Seleoxl technology in foreign countries and NHD technology in China; this technology is listed in the National Key Industries Cleaner Production Technology Orientation Catalogue of the State Economic and Trade Commission.

Wet decarbonisation is a widely used decarbonisation process with low energy consumption and is widely used to remove CO2 and H2S from ammonia, methanol feedstock gas, refinery gas, city gas and natural.

FAX:028-86198015

ADD:13/F, Building 1, Caiji International, No. 595 Jinzhou Road, Jinniu District, Chengdu, China